JHMT is one of the leading manufacturers of the grinding balls in China. Since 2013, it commenced providing the optimum grinding balls to the mining industry with the excellent abrasion resistance and impact resistance. JHMT is located in Huashi Town, Jiangyin city, Jiangsu Province, in the centre of the YRD with advantageous location and convenient traffic. It covers an area of 27,000 square meters, including 12,000 square meters of plant building, equipped with seven production lines, and the capacity reaches to 120,000 tons per year.

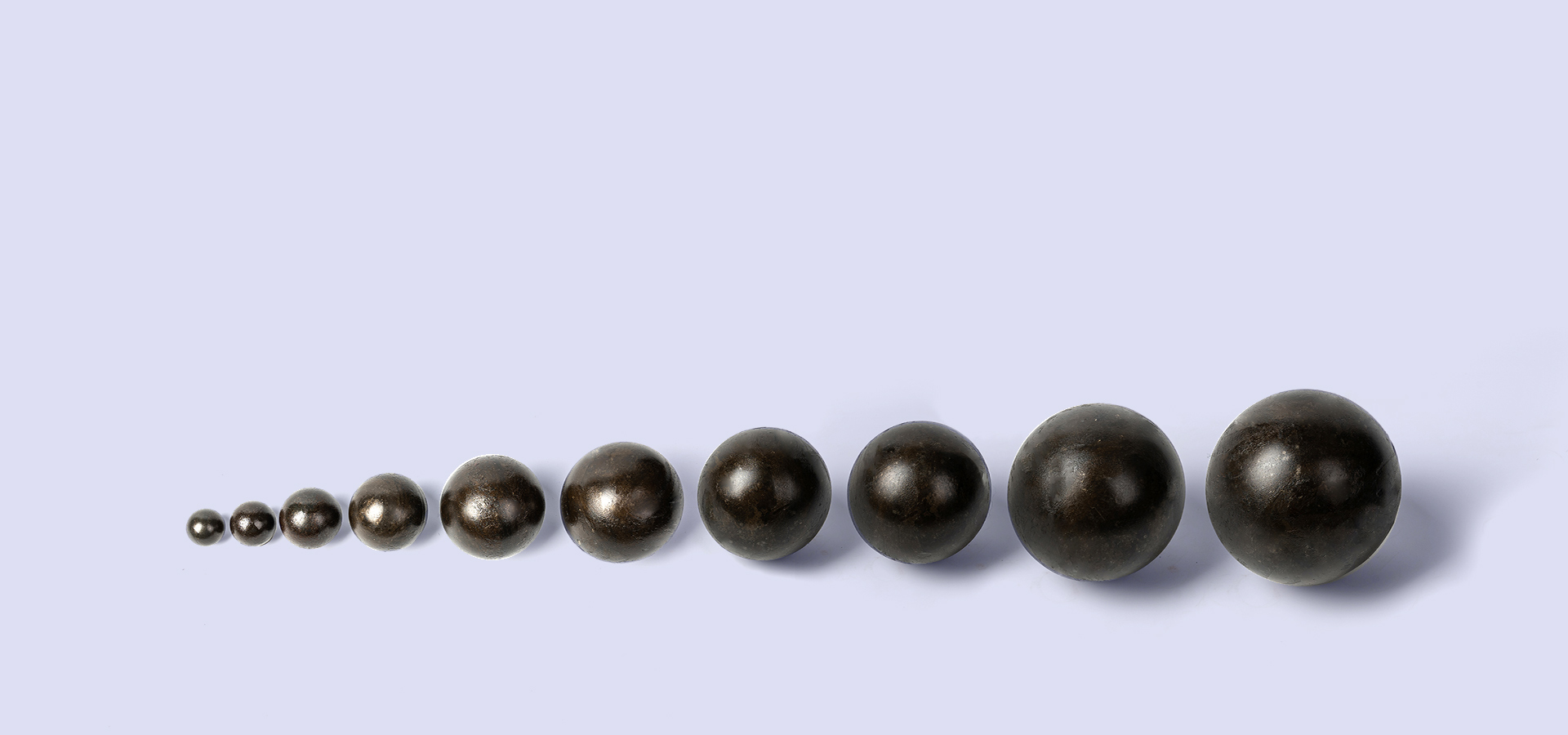

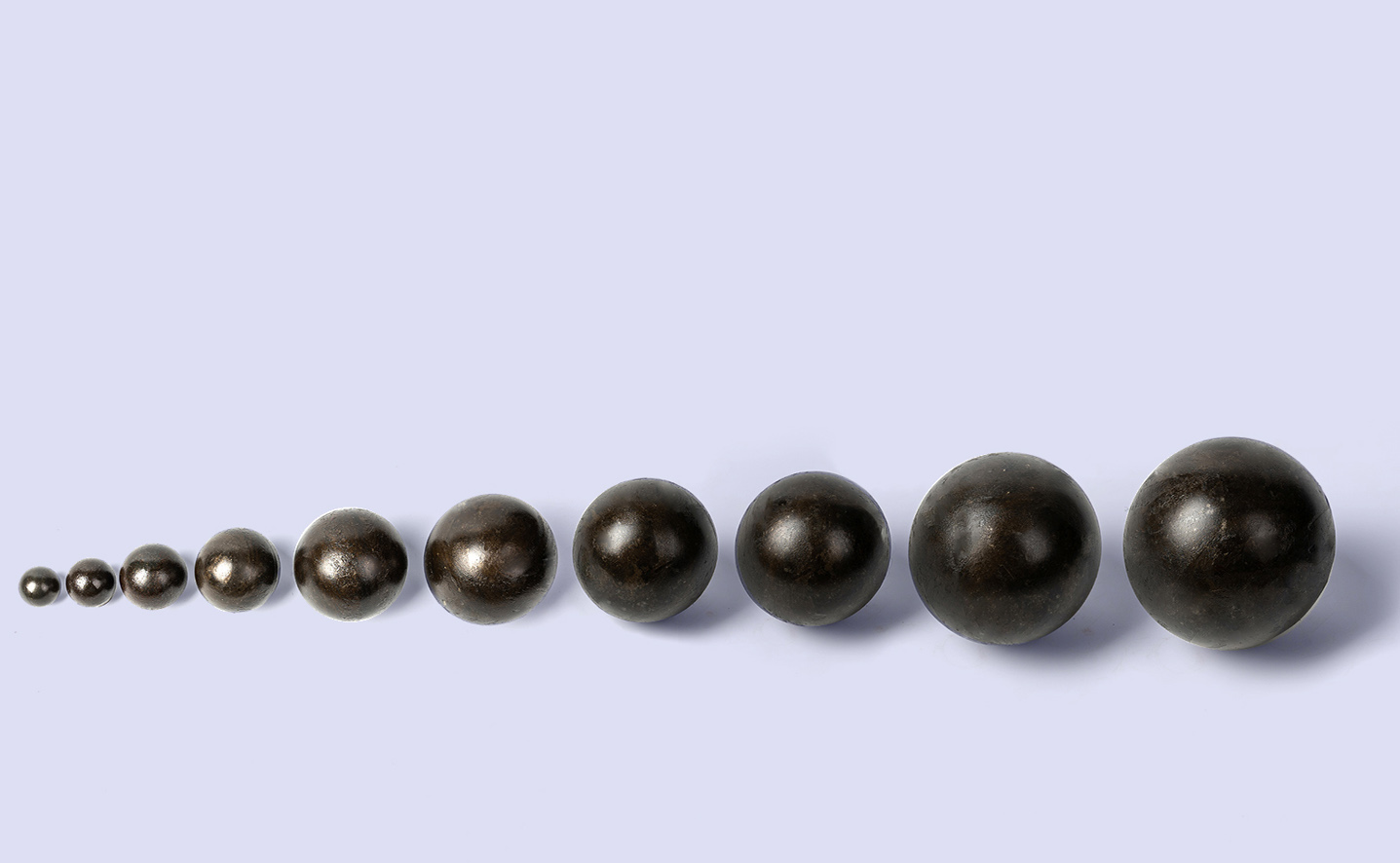

JHMT specializes in production of Ф20mm-Ф125mm grinding balls with premium quality. We also provide sustained technical services and energy saving solutions to our customers, aimed to achieve the highest customer satisfaction.

WHY CHOOSE USJHMT has grown into a professional scaled supplier with stable product quality and advanced production technology. And our products have been exported to more than ten countries and regions in the world. We are seeking for greater perfection and have the greatest confidence that we will improve the operation efficiency for the grinding and processing of minerals in the mining industry.

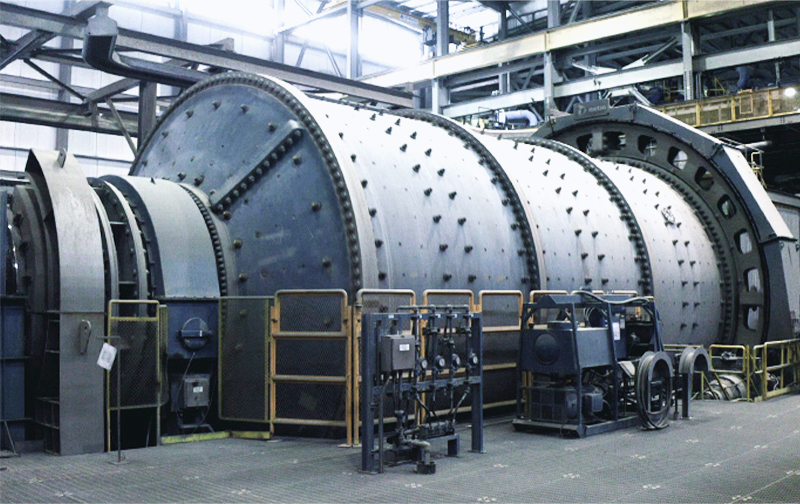

The SAG mill is used primarily for SAG ore grinding operations with a high impact

environment.

JHMT focus on obtaining a balance between abrasion resistance and impact resistance by using raw

material with specific chemical composition and special heat treatment process.

After careful consideration of the different operation situations of the SAG mills, there is a deliberate selection for both alloy content and hardness level through the special heat treatment processes, the objective of which is to obtain optimum abrasion resistance and impact resistance.

The ball mill is used primarily for secondary ore grinding operations with a lower impact environment. JHMT focus on achieving the high abrasion resistance and impact breakage resistance.

CHEMICAL COMPOSITION & HARDNESSUsing the high carbon alloy steel bars and there is a deliberate selection for both alloy content and hardness level through the special heat treatment processes, the objective of which is to obtain the high abrasion resistance and impact resistance.

Our products are widely used in industries including metal process industry, thermal power industry, cement industry, non-metallic crushing industry, etc.